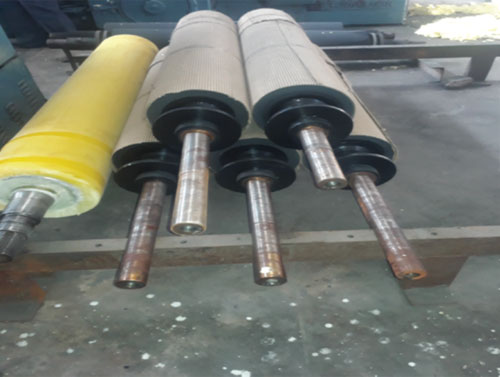

PU Rolls

Polyurethane (PU) rolls are widely used in cold rolling mills for their high wear resistance, durability, and ability to handle extreme pressures. These rolls provide excellent grip, shock absorption, and surface protection, making them ideal for steel processing applications.

Key Features:

- High abrasion resistance: Ensures long service life.

- Superior elasticity: Absorbs shocks and prevents surface damage.

- Non-marking properties: Prevents scratches on processed steel.

- Temperature resistance: Performs well under varying thermal conditions.

- Customizable hardness: Available in different Shore A and Shore D hardness levels.

Applications:

- Bridle Rolls: Used for tension control in rolling mills.

- Deflector Rolls: Guides steel strips during processing.

- Support Rolls: Provides stability and uniform pressure.

- Coating Line Rolls: Used in galvanizing and color coating lines.

- Steel Melt Shops – Essential for maintaining stable electrical connections in steel production.

- Electrochemical Processing – Used in high-current industrial applications

- Categories: